So

you like the look of a fine wooden base for your model, but you donít want

to drop the scratch on a finished base. Thatís fine. With a small investment

and a little elbow grease you can have nice looking wooden bases.

To

make this even easier on you, I will assume that somewhere in your general

area you will have some sort of craft store like Michaelís, The Rag Shop,

etc. If you had to cut the boards yourself youíd need a router and a lot

more sanding time. That is what we are trying to avoid here. So, to get

started take a trip to the craft store. Find where they keep their bases and

take your time picking some out. The nicer the cut of the wood, the easier it

will be on you later on. These usually run under $1 each in the craft stores!

WHAT

TO LOOK FOR:

A GOOD cut! If two sides are rough (even the round ones can and will have two

rough sides) that means more sanding. Bases

with an interesting grain that will look good once stained. Bases that feel

HEAVIER are great because it might be a denser wood and will accept your work

very nicely. Avoid warped bases, major dents and other damage, rough cuts, and

splintering wood. These will only hinder you later on.

SUPPLIES:

Various woodstains, polyurethane, various sandpapers, various grains of steel

wool, 1 or 2 inch bristle paintbrushes, paper towels.

So

youíve gathered up your supplies. You probably have some of this already and

can get going for less than $10. Time to get to work. Grab a base. Inspect it.

Run your fingers all around it. You WILL notice some rough spots. So dig out

your sand paper and get to work. Try to smooth it out as best you can. Since

these are usually a fairly soft wood, you may never get it smooth at this

point, but thatís alright. You can fix it up later.

Sanding

the rough sides.

When

you are satisfied with the surface of the wood, the next step is stain. I like

the darker colors like English Chestnut. Also I prefer the oil-based line by

Minwax, as opposed to their water-based line. It just seems to penetrate

better and the color is richer.

NOTE:

Donít be fooled by the ones that say itís stain and clear gloss

combined, it NEVER turns out glossyÖ EVER!

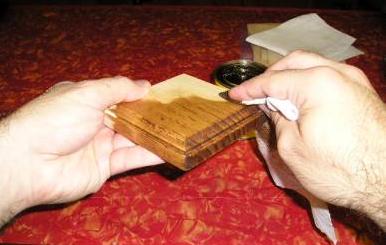

Massaging

in the stain.

Crack open your can of stain and

dunk in your paper towel or rag and massage the stain into the wood evenly. If

you feel like you mightíve used too much stain you can rub the wood with a

clean towel to soak up some of the stain. I like to use a towel because I feel

that I have more control over the effect of the stain. When you put it on with

a brush, it can all soak in before you have a chance to start wiping it off

and you can end up turning your base black and featureless quickly. HOWEVER,

if you had any rough sides on your base, they WILL turn black with the stain.

Donít worry about it. You can still fix that later.

Applying

the polyurethane.

Sanding

down those dark areas.

Steel

wool the surface smooth.

I like to let the wood sit for a

little while before applying the first coat of polyurethane. Minwax suggests 8

hours, but I think you can get away with less if you donít use a lot of

stain. I prefer the gloss finishes on wood, so I get the Minwax Gloss Finish.

Apply a nice even coat of polyurethane and allow at least a day to dry. This

is the point when you get to fix up those areas that became too dark while in

the staining process. With a fairly fine sandpaper you must now smooth out

those dark areas, as well as sand the entire surface of the base. Donít

worry if you sand through the stained wood, you can easily re-apply more stain

to those areas. Steel wool the base until itís smooth. Now you should have a

pretty uniform finish on all the surfaces and itís time for your second coat

of polyurethane. Once dry, evaluate how it turned out. More than likely you

will need at least one more coat of polyurethane to attain the best finish. If

you think it leaves more to be desired, feel free to sand and polyurethane as

many time as you see fit until you get the level of gloss that you want. I

usually put down about four coats before considering it done. At that point

you will have a professional looking base that probably cost you less than a

dollar in materials to make.

Donít

forget to clean your brush. Soak it in Lacquer thinner and wipe it clean.

Donít leave it in too long, itíll dry out the bristles and they will begin

falling out prematurely.

The

finished product. After four rounds of sanding and coating this base has a

rich color and deep shine!

Good

luck!

This

is from the September, 2004 Issue of the BPMS Bulletin.

If

you liked this, we have lots of useful clinics at the Brooklyn Plastic

Modelers Society all the time. For meeting information please check out our

webpage:

BPMS